Explosive gas mixtures, vapors, mists, or dust clouds are produced as a side effect of production in many branches of industry. These include the pharmaceutical and chemical industry, the printing and paper sectors, but also areas such as cereal or sugar processing. In these companies, intralogistics trucks must guarantee the maximum level of explosion protection in order to avoid accidents.

Numerous counterbalanced trucks, reach trucks, pallet stackers and pallet trucks from Linde Material Handling are therefore available in explosion-proof “Ex” versions, meaning that the entire material flow in a company can be conducted under explosion-proof conditions. Components which could trigger sparking, such as drive components, wheels, or even lifting forks, are protected through surface treatment.

In addition, the surface temperature of individual truck components is regulated in order to prevent overheating. Despite this additional equipment, the trucks retain the cost-effectiveness, handling performance, and ergonomic design typical of Linde.

Numerous counterbalanced trucks, reach trucks, pallet stackers and pallet trucks from Linde Material Handling are therefore available in explosion-proof “Ex” versions, meaning that the entire material flow in a company can be conducted under explosion-proof conditions. Components which could trigger sparking, such as drive components, wheels, or even lifting forks, are protected through surface treatment.

In addition, the surface temperature of individual truck components is regulated in order to prevent overheating. Despite this additional equipment, the trucks retain the cost-effectiveness, handling performance, and ergonomic design typical of Linde.

Standard-Compliant in Hazard Zones

The legal requirements for explosion protection are constantly being further developed and standardized. It is important to implement these promptly and correctly. The Linde trucks and warehousing equipment with explosion protection, as well as the corresponding documentation, are all state-of-the-art. They comply with the EU regulations on use in potentially explosive atmospheres (EN 1755) and the ATEX Guidelines 2014/34/EU.

CE conformity is ensured by the use of harmonized standards in the development process. All relevant components, devices and modules, as well as the whole truck must undergo a type test or be certified by an accredited, reputable testing center. Linde provides trucks for use in potentially explosive atmospheres due to gas, vapor or dust, which occur occasionally (Zone 1/Zone 21) or for a short time only (Zone 2 / Zone 22) during normal operation. Trucks in categories 2G/D and 3G/D are adapted exactly to the corresponding conditions of use, which are derived from the customer’s explosion protection document.

Explosion-Protection Measures

Linde trucks are specially designed to meet the requirements for working in potentially explosive areas and combine the familiar advantages of series-produced trucks with comprehensive explosion-protection measures pursuant to the ATEX product guidelines.

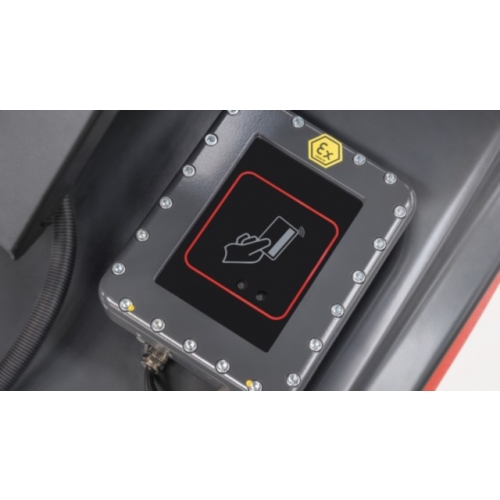

Electrical equipment such as motors, controls, sensors, switches or displays are protected in using different protection measures. Linde uses flameproof enclosure, increased safety, intrinsic safety, encapsulation, sealed devices, non-sparking equipment and restricted breathing housings.

Mechanical equipment is protected through constructive measures. The formation of mechanical sparks is avoided on the forks and brakes. Plastic components such as floor mats, tires, tanks and seat covers are protected against hazardous electrostatic charges.

Electronic temperature monitoring ensures that no excessively high temperatures are reached under extreme operating conditions.

The legal requirements for explosion protection are constantly being further developed and standardized. It is important to implement these promptly and correctly. The Linde trucks and warehousing equipment with explosion protection, as well as the corresponding documentation, are all state-of-the-art. They comply with the EU regulations on use in potentially explosive atmospheres (EN 1755) and the ATEX Guidelines 2014/34/EU.

CE conformity is ensured by the use of harmonized standards in the development process. All relevant components, devices and modules, as well as the whole truck must undergo a type test or be certified by an accredited, reputable testing center. Linde provides trucks for use in potentially explosive atmospheres due to gas, vapor or dust, which occur occasionally (Zone 1/Zone 21) or for a short time only (Zone 2 / Zone 22) during normal operation. Trucks in categories 2G/D and 3G/D are adapted exactly to the corresponding conditions of use, which are derived from the customer’s explosion protection document.

Explosion-Protection Measures

Linde trucks are specially designed to meet the requirements for working in potentially explosive areas and combine the familiar advantages of series-produced trucks with comprehensive explosion-protection measures pursuant to the ATEX product guidelines.

Electrical equipment such as motors, controls, sensors, switches or displays are protected in using different protection measures. Linde uses flameproof enclosure, increased safety, intrinsic safety, encapsulation, sealed devices, non-sparking equipment and restricted breathing housings.

Mechanical equipment is protected through constructive measures. The formation of mechanical sparks is avoided on the forks and brakes. Plastic components such as floor mats, tires, tanks and seat covers are protected against hazardous electrostatic charges.

Electronic temperature monitoring ensures that no excessively high temperatures are reached under extreme operating conditions.